09 May 2024

|

Replacing brake fluid at the prescribed two or three yearly intervals is often thought unnecessary, but are there good reasons behind this? Ed Evans explains the facts

Ever jumped out of your old Land Rover and into a modern car and noticed how sharp the brakes are? That effect is not just because of technical advances, it’s much to do with the condition of the brake fluid and the associated hydraulic seals inside the braking system.

Yet, although Land Rover service schedules specify regular renewal of brake fluid, and of brake seals, many non-Land Rover garages ignore this requirement and vehicles seem to carry on driving (albeit with the occasional routine brake problem). So, is a regular fluid change really necessary, or is Land Rover simply covering itself by making the stipulation, and enjoying some extra service business?

The main consideration is that brake fluid is hygroscopic – it absorbs moisture from the atmosphere – and when the moisture content reaches just three per cent it can significantly reduce the fluid’s ability to withstand high temperatures. Brake discs can reach between 400°C and 700°C in use and, while much of that heat is dissipated to the air (more rapidly so with ventilated discs) much of it is transmitted into the calipers and to the fluid inside them. This reduces the hydraulic effect of moisture-contaminated fluid, which means less pressure is applied to the wheel brakes no matter how hard the pedal is pressed. So, how can moisture get into a brake system that is supposedly fluid-tight? We’ll come to that later.

Hydraulic loss

If moisture-contaminated fluid is left in the system, the caliper pistons will be the first to corrode, leading to sticking brakes where the pad does not retract from the disc.

For now, let’s concentrate on the effect of that moisture ingress. The boiling temperature of water is 100°C, whereas that of new DOT4 brake fluid is typically around 230°C. So the more water is absorbed by the fluid, the lower the average boiling point, and when that reaches 180°C the system is considered potentially dangerous. During heavy or prolonged braking such as descents, especially when towing or fully loaded, or just hard driving, the brakes become hotter and there is more chance of the fluid reaching its boiling point, causing moisture in the fluid to vapourise. Vapour is far more compressible than the original fluid, so this absorbs some of the brake pedal movement instead of delivering it to the calipers’ pistons. Thus the braking force at the wheels is reduced, so more effort needs to be applied to the brake pedal which now feels soft and spongy – brake fade, as we refer to it.

Corrosion and wear factors

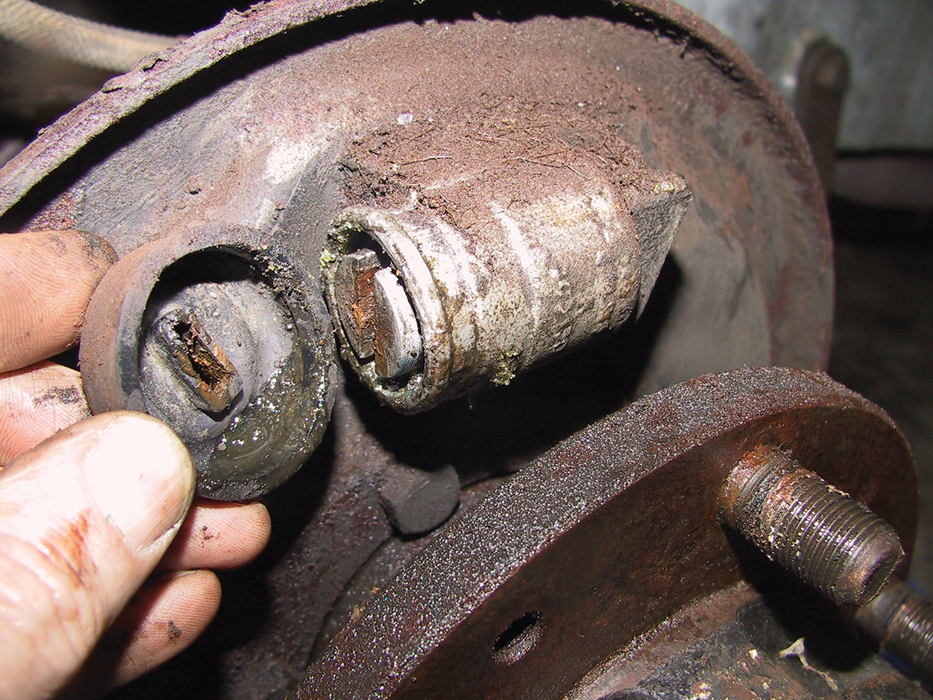

These four-pot caliper pistons show how moisture in old brake fluid can cause pitting on the working surfaces which, in turn, can damage the seals.

Moisture in the fluid also causes corrosion of internal parts such as the pistons and cylinder bores in calipers, drum brake cylinders, and precision components of ABS assemblies. Brake fluids do contain corrosion inhibitors but, as with those in antifreeze, they have a finite life and their task is made more difficult as moisture increases. Corrosion produces roughened metal surfaces which wear away at the adjacent seals to produce fine particles which become suspended in the fluid. This can cause sludge build-up, interfering with the free flow of fluid and the operation of small components such as ABS valves. Good brake fluid also lubricates seals and the moving metal components in the system, and this ability is also reduced by the presence of moisture.

If the brake fluid is this colour, there’s definitely corrosion in the system and damage to seals. New fluid and seals are needed all-round

Debris from eroded and worn seals will show as discolouration in the fluid that is leaked or bled from disconnected components during repair. It’s a sign that a complete fluid change is overdue. When replacing all the fluid, it’s worth first emptying the fluid reservoir and cleaning inside with a lint-free cloth to prevent deposits being washed through.

Quick corrosion: This relatively new SIII drum brake cylinder already has a ring of corrosion inside. The cylinder was bled with new fluid, but moisture permeated from old fluid elsewhere in the system to corrode it.

How moisture gets in

Leaking out and in: If fluid is leaking out when the brakes are applied, no matter how slightly, there’s every chance that air will be sucked in when the brakes are released. (Series III pictured)

Moisture can be drawn into the fluid past worn piston seals on the calipers when the brakes are at rest or released, or through the fluid reservoir which is always vented to atmosphere and via porosity in old flexible hoses. It can also be absorbed when parts of the system are opened for repair work.

Ingress: When bleeding brakes, the tube fitted to the bleed nipple must be soft and airtight, not loose, otherwise air will be sucked in while retightening the nipple

When bleeding the brakes, it’s important that old fluid being bled out into a jar is not re-used because this has been very exposed to air in the jar. Even after repair and subsequent bleeding, tiny pockets of air can remain in some components. Rubber boots over the drum cylinder pistons, and dirt seals on caliper pistons, are not necessarily airtight, so moisture has access past these and to the fluid seals which, if worn, can allow air in when at rest, even though they remain fluid-tight in the opposite direction. Remember, moisture doesn’t get in by chance, the fluid actively absorbs it.

Perfection: These new parts show how the piston surfaces should look. There’s little chance of these damaging the new seals, provided the fluid is regularly replaced

For the same reason, bottles of new fluid should be kept tightly capped to exclude air, though once some fluid has been poured out there will be a presence of moisture in the air in the bottle, which will be absorbed. A typical shelf life is three years.

Checking the fluid for moisture content

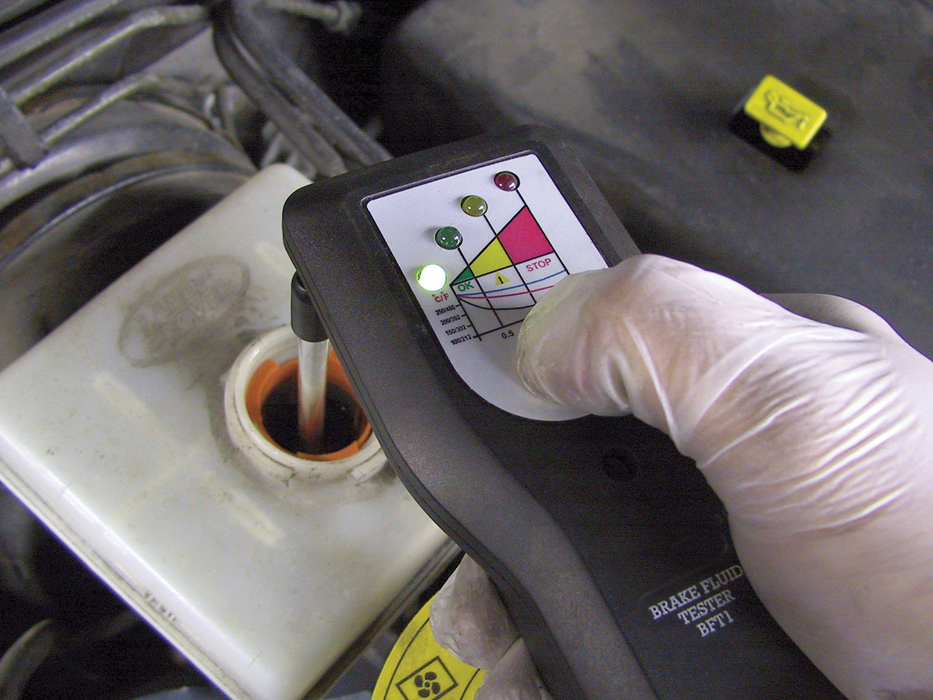

Moisture test: This electronic brake fluid tester measures conductivity within the fluid reservoir. It may be worth collecting fluid from downstream during repairs, and test that too

Assuming the moisture is distributed evenly throughout the brake fluid, there are two ways to check moisture content at the brake fluid reservoir. The first method involves removing a sample of fluid and testing its actual boiling point; if below 200°C fluid replacement is advised, below 180°C the fluid is in a dangerous condition and needs immediate replacement. A boiling point test kit is relatively expensive and likely to be available only at a garage. The second method involves an electric fluid checker costing less than £50 which is dipped into the fluid reservoir and an electrical current passed between the submerged electrodes. This measures the electrical conductivity of the fluid, which varies with the moisture content.

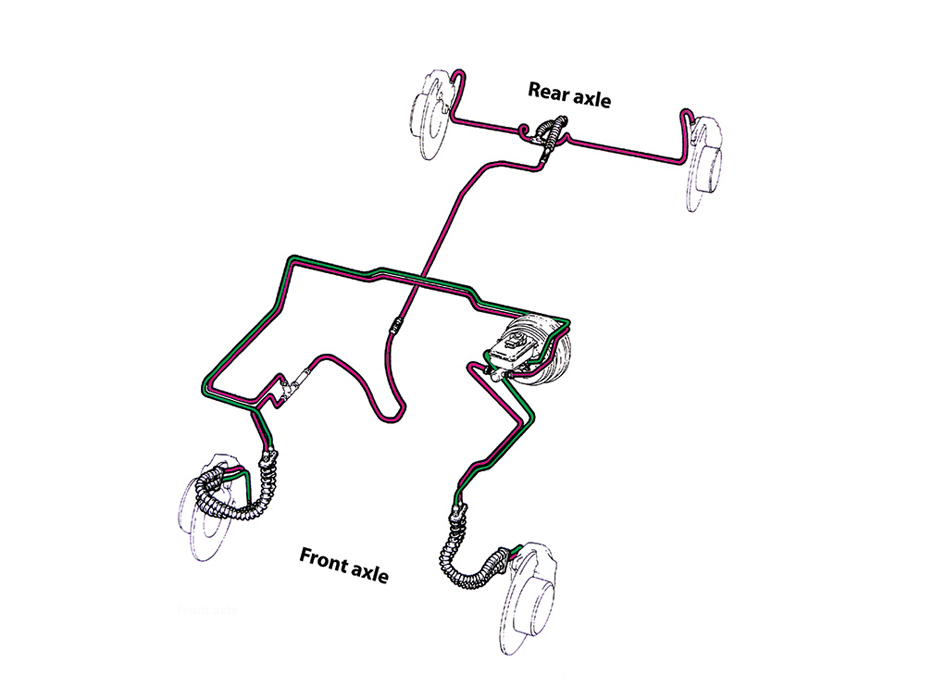

A fluid test in the master cylinder reservoir may not necessarily be representative of fluid elsewhere in this convoluted Discovery 1 dual brake system

But these methods only check the fluid in the reservoir, and that may have been topped up recently to account for pad wear, or if there is a leak in the system (which should be fixed immediately) or if part of the system has been bled after repair work. Just how long existing moisture would take to migrate up into the new fluid in the reservoir is unclear, so the reading taken at the reservoir may not indicate the condition of the fluid in other parts of the system. For example, if a front wheel brake has been recently bled, the fluid in the reservoir and along the line to that brake would be fresh, but old untested fluid would remain in the rest of the system. So it’s better to test the old fluid that is lost when disconnecting the system or bled out after a repair and, if its condition is unsatisfactory, to then replace the fluid throughout the system.

Types of brake fluid

There are two significant types: glycol-based and silicone-based, categorised as DOT 3, 4, 5.1 and 5. DOT stands for Department of Transportation (USA). The numbers give an indication of relative boiling points – the higher the number, the higher the boiling point.

Critical part: Always use the correct specified brake fluid and keep it in good condition. Regular fluid renewal helps ABS work more efficiently and last longer

DOT3 fluid that we use in older Land Rovers has a greater resistance to moisture absorption than DOT4 does. However, DOT3 has a lower boiling point and so is unsuitable for the increased performance and more powerful brakes of later Land Rovers (and performance modified earlier models) – remember that all the braking effort is turned into heat, much of which soaks through the brake components and into the fluid. So we use DOT4 for its ability to resist boiling and therefore perform better. The downside of DOT4 is that it absorbs moisture more quickly than DOT3, which is a reason why service schedules stipulate its more frequent replacement. But it’s essential to use DOT4 where specified by Land Rover, partly because it has the correct viscosity to work with the ABS system on which braking safety and traction control depend. DOT4 can be used in a vehicle where DOT3 was originally specified, but needs to be changed more frequently. Brake fluid types should never be mixed. Always confirm the fluid specification with your vehicle handbook.

Answer to the question

If we want maximum safety and maximum service life for brake components, we should follow Land Rover’s advice and adhere to the schedules. A fluid change should take around two hours with reasonable DIY facilities, and some of the quick, in-out, service specialists will do the flush and fluid change for around £50. Additional costs may arise if bleed nipples are seized, leading to component replacements, but that work needs doing anyway. And for some models diagnostic kit may be needed in respect of ABS components. If your truck is fully serviced by a Land Rover dealership or good independent, it can be expected that the fluid replacement is already up to date.

Like to have your own Land Rover library?

Try our All-Access Digital Subscription. You'll get access to over 7 years of Land Rover Monthly – that’s more than 100 issues plus the latest digital issue. All issues are fully searchable so you can easily find what you are looking for and what’s more it’s less than 10p a day to subscribe. Click the link above to find out more details and start enjoying all the benefits now.