02 June 2024

|

Series-type Land Rovers run happily with either type of springs but, when converting to parabolics, there’s more than just new springs to consider

Fitting parabolic springs to Series I, II and III models has always been a controversial issue. A recently important part of the controversy is that because they were never fitted as standard, they detract from originality. And in addition to obvious differences in appearance and construction, the two types give different ride and handling characteristics.

The Spanish company, Santana, known for its own versions of Land Rovers, fitted parabolic springs as standard to its Series III models, claiming them to give superior performance. My own view is that original-type springs in good condition give the best compromise of ride, handling and load capability, while parabolics give improved ride comfort and – importantly for off-road driving – increased axle articulation.

Whether fitting parabolic or standard springs, it’s important to buy from a reliable source to ensure the stance and ride characteristics are what you’d expect. Having the correct dimensions so that the spring fits is not enough. Standard-type springs need to be made of the correct material specification with the appropriate metallurgical treatments to ensure they perform as Land Rover intended. Standard and parabolic springs are available from many of the Land Rover aftermarket suppliers, and from British specialist manufacturer, Jones Springs (Engineering) Ltd of Darlaston: jones-springs.co.uk

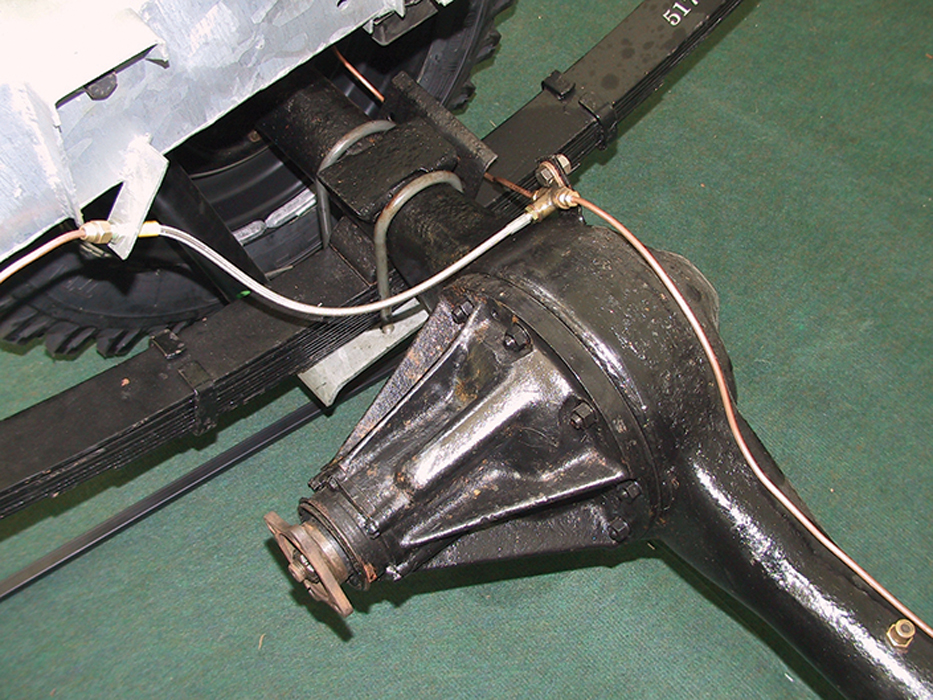

The value of straps: Axle straps (where fitted) prevent the damper reaching the limit of its extension. Parabolics and matching dampers may need longer straps.

Hoses long enough? Standard brake hoses may not be long enough to deal with the extra axle movement afforded by parabolic springs. Longer hoses are available.

How to fit Parabolics

In our next feature, Replace Leaf Springs with Parabolics, we'll show you the process of removing the old standard springs and replacing with new parabolics on the rear of a Series III. Of course, replacing the front springs will be done in the same way, and the process is similar when replacing with original-type springs. Changing the dampers on a Series model is so simple as not to need any explanation. Naturally, we strongly recommend replacing all four springs and fitting matching new dampers all-round.

When the conversion is complete, brake lines should be checked for leakage, and all spring and damper fasteners should be rechecked for tightness after around 20 miles of driving.

Staying with standard springs

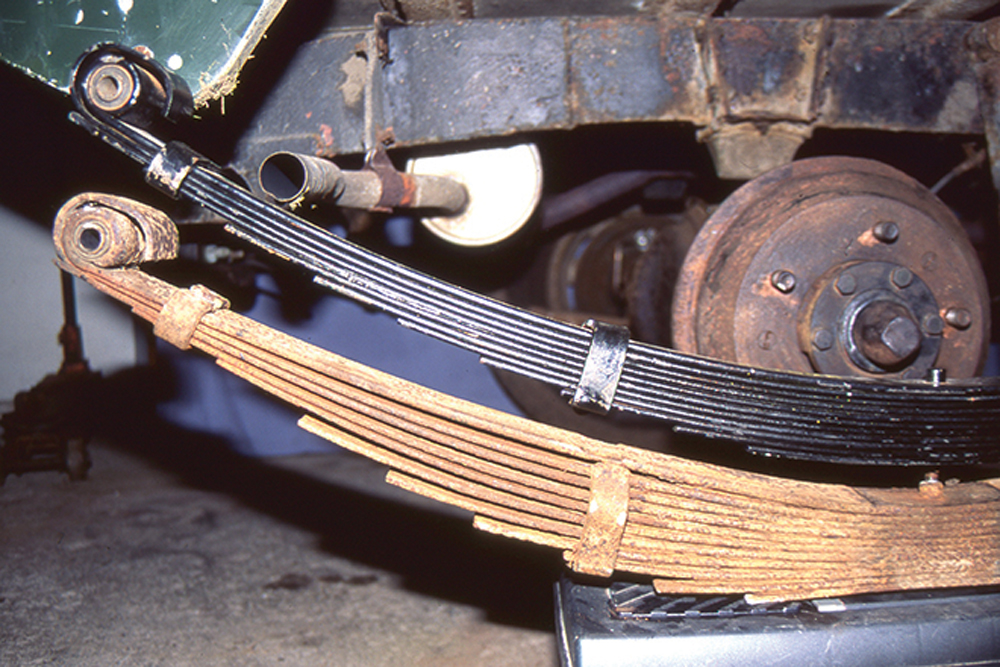

What goes wrong with standard springs? Overloading and long-term use can cause spring leaves (including parabolics) to crack, often close to or around the forward mounting points. Because standard-type leaves are closely packed, their surfaces need to move against each other as the spring flexes, but rust building up between the leaves can restrict movement and, in severe cases, the build-up of rust can force the leaves apart, eventually deforming the spring clamps. Cracked or rust-blown springs need to be replaced and, while it is possible to have individual leaves renewed, in reality we’d just go for a complete new spring, and we’d always replace them in axle pairs.

Rust blown: Tired and neglected leaf springs rust between the leaves, forcing them apart and expanding the steel clamp that should hold them tightly together.

Letting go: Keep an eye on the spring clamps. Overloading can force the clamps outward from the top until the leaves no longer support or work properly with each other.

Crack point: Overloaded, abused or high-mileage upper spring leaves can crack where they turn around the chassis bush (front and rears at forward mounting).

Rust in peace: The chassis of a Land Rover in use would never get into this state, but it’s a reminder to confirm the integrity of the chassis around the spring mounts – stress and corrosion are a bad mix.

Drag clamp: When checking SIII front left spring at service time, note that the drag link clamp does not foul the top of the spring.

Maintaining standard springs

A popular trick was to grease the springs and then fit purpose-made leather sleeves over them. This made sense because the grease prevented rust and helped lubricate the inter-leaf movement, while the leather sleeves prevented grit getting in between the leaves where it would be attracted and held by the grease.

Apply a mixture of petrol and clean engine oil to the springs using a paint brush, and allow it to soak in between the leaves. The plan is that the oil prevents rusting (and attracts less grit than grease), while the petrol thins the oil so it can more easily seep between the leaves. The petrol will evaporate away, leaving the oil. Petrol is not a good thing to work with, so the usual precautions such as hand and eye protection, no risk of sparks from electrical equipment, and good ventialtion all apply, and never use petrol in a pit.

Like to have your own Land Rover library?

Try our All-Access Digital Subscription. You'll get access to over 7 years of Land Rover Monthly – that’s more than 100 issues plus the latest digital issue. All issues are fully searchable so you can easily find what you are looking for and what’s more it’s less than 10p a day to subscribe. Click the link above to find out more details and start enjoying all the benefits now.