29 October 2022

|

Fancy tackling a near basket case? In part one of this series, Trevor Cuthbert gives his first assessment of the Td5

Need to know

Time: Around 2 hours.

Cost: £0

Difficulty: 1 out of 5 stars

Models: Defender, Ninety/OneTen

Tools needed: Hammer, screwdriver, vehicle lift

Parts used: None required at this stage

Work safely:

• Make sure the raised vehicle is stable before and during the inspection and is supported by correctly rated equipment in good order.

• Wear eye protection when working under dirty parts and components.

• Wear protective gloves.

• Wear safety boot or shoes.

• Consider wearing a bump cap under raised vehicle.

This Defender 110 Td5 hard top version was offered to me about eight years ago by an owner who had given up on the many problems associated with it. I had no particular use for a vehicle that would barely run. Its engine had seriously overheated, there wasn’t a straight body panel on it, the gearbox was clunky and the recorded mileage was epic, but I purchased it because the asking price was low. The interior smelled badly too, as the owner’s German Shepherd had possibly spent many more hours within it than the owner himself.

But quite a lot of money had been spent on it, so there were plenty of useful new parts that could be harvested if the decision was taken to dismantle it. Three years later, it did get partially dismantled when a chap wanted to buy it from me for the body panels – even though they were in poor condition. If he had offered slightly more money, I would have let him take the complete vehicle, but in the end we settled on a deal where he removed what he needed and brought the rest back.

When the 110 was returned, I could see the bulkhead and chassis were in remarkably good condition and, although the engine was bad, the associated Td5 components were all intact. So when I ended up with a very good 15P Td5 engine and transmission from the recent failed Discovery 2 rebuild project, I decided to rebuild the Defender.

So, this series will track what I need to do to the remains of the 110 – the rolling chassis – to make some form of serviceable and reliable vehicle. I will not be covering the finer details of building up the 110, which has been comprehensively covered many times already. Instead, I will focus on some of the interesting jobs that come up during the build, while keeping you updated on the general rebuild work that takes place.

The first thing I need to do is bring the poor old thing into the workshop and refresh myself on exactly what I have got here – and what is going to be needed to get the Land Rover on the road again.

General bodywork

With a fresh battery in place, the ignition was switched on and the fuel gauge indicated a three-quarters full tank. Surprisingly, although the overheated engine is lumpy, noisy, uneven and smokey, it actually starts up quite easily. The clutch system

is working normally, and so the vehicle is drivable along the short distance from storage barn on to the trailer, and from the trailer straight into my workshop.

Clearly, most of the bodywork has gone. The Land Rover is left with

one left-side front wing (badly dented), two front doors that have seen better days, a bulkhead that appears to be quite good, and the seat box with floor plates that are perfectly serviceable.

Stored in an old shed: Not quite a ‘barn find’, but more like ‘kept in the corner of the hay barn, until I figure out what to do with it’.

Unloved and bombed: The engine was in bad shape, so it didn’t seem to matter that the bird population of the barn began to use it as their toilet.

Intact at least: The dashboard, instruments and controls are all present and largely working normally, although things are a little tatty – nothing that can’t be put right.

Bulkhead and underside

When the Defender came back to me, having had most of the body panels removed, the bulkhead was generally more visible than would usually be the case. If I had witnessed rotted-out footwells and other serious corrosion, the fate of the remaining Land Rover would have been sealed. However, because the bulkhead appeared to be in good shape, I decided to store the Land Rover. Today we would not consider scrapping a Defender, but five years ago one like this was actually a marginal decision. However, holding the vehicle in abeyance for those few short years has seen many attitudes change, my own included. So, no matter what this inspection and assessment reveals, this 110 will definitely be rebuilt – I just need to determine what the cost will be.

Good for its age: The top of the bulkhead seems to be in good condition, with no sign of rust having penetrated through to the outer surfaces, as is commonly seen.

How did this start? Inevitably, there has been some rust damage to the bulkhead, although this corrosion above the footwell is unusual. Repair should be fairly easy in this location.

A pleasing sight: The footwells are original and in remarkably good condition. This area of the bulkhead is often first to be penetrated by rust and is therefore the first to see repairs.

One original, one new: The bulkhead outrigger on the chassis at the driver’s side is getting a little crusty with rust, but is still solid. The passenger side has been replaced.

Holding up well: From underneath, the outside of the battery compartment appears quite solid, although there’s one localised small hole through the metal. Inside is a different story.

Solid Salisbury: The rear axle casing and associated brackets are all in good condition. The casing would benefit from a coat of paint, but is otherwise ready to go to work.

Polyurethane not rubber: The rear trailing arms have had their axle bushes and chassis bushes replaced with new ones, most likely from the Polybush range, probably the Dynamic grade.

New parts: The rear brake discs and calipers have recently been renewed, so there shouldn’t be much work to carry out on this section of the braking system.

At the front: The two large bushes that sandwich the chassis bracket to hold the front radius arms have also been replaced recently and are in excellent condition too.

Road handling should be OK: The tricky-to-replace front axle to radius arm bushes complete the picture of a Land Rover that has had its suspension links inspected and fully upgraded.

Good joints: The front swivel seals are only letting a minimal amount of oil leak out, and the swivel balls are in good condition with no advanced pitting.

Often overlooked: Another sign that the Land Rover has received some proper maintenance is that the A-frame ball joint at the rear axle has been replaced with a new assembly.

Wolf wheels: The Land Rover has a full set of five Heavy Duty steel wheels, with usable All Terrain tyres – this is an excellent combination for a working vehicle.

Fuel system and rear of chassis

Compared with previous Land Rover engines, where a later engine design could be readily transplanted into an early vehicle, things are not so straightforward with a Td5. To run a Td5 engine successfully, a number of parts and systems are needed, such as the complete fuel system front to back, specific fuel hoses, fuel filter housing, fuel tank and fuel pump. The complete bulkhead wiring loom and chassis wiring harness are also needed, as are the dashboard instruments, particularly the speedometer.

The good news with this vehicle is that the whole Td5 installation is present, albeit with a completely failed engine. Everything is intact and functioning correctly, making this a viable project without too much searching for expensive parts.

Unmolested: The fuel system seems to be all intact and in good order. There are no signs of chafing on the fuel hoses and, other than a rusty tank strap, it is all good.

Another costly replacement: The fuel filter housing is known for becoming porous and leaky; this one is a recent replacement, with new filter and even a new cover.

All looking good: The fuel filler hose and the chassis wiring harness are emerging through a very solid rear quarter of the chassis, which has clearly been renewed in the past.

No nasty rust holes: As part of the rear quarter chassis replacement, the fairly new rear crossmember looks resplendent and solid, with an adjustable towing bracket fitted.

Exhaust: The exhaust middle silencer, front pipe and tailpipe all look serviceable for miles to come. This wiring harness here also looks to be intact and ready to go.

Excellent frame: As well as the new bulkhead outrigger on the chassis left-side, this body outrigger has been replaced, meaning that overall the chassis is now very sound.

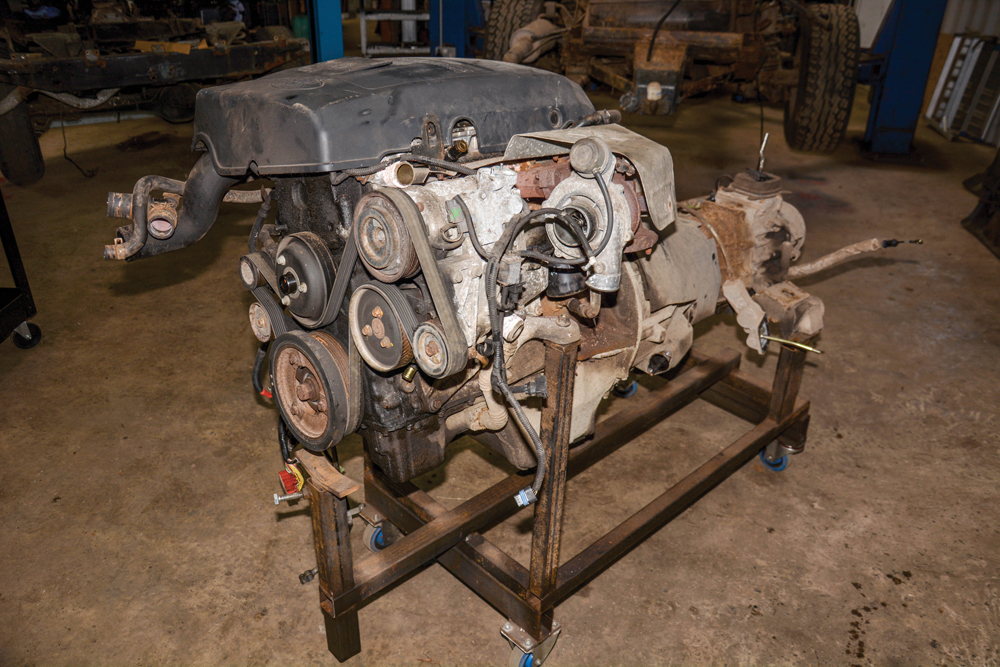

Biggest problem solved: This 15P Td5 engine from the failed Discovery 2 project will replace the old 10P engine, which suffers from multiple issues – offering a cost-effective way of getting mobile again.

There are a number of options on how this Defender 110 could be rebuilt in terms of body configuration. The Land Rover left the factory at Sollihull as a hard top model. However, it could become a pick-up truck. Or how about a High Capacity Pick Up (HCPU)? There also exists the possibility of making it into a soft top model or a passenger-carrying Station Wagon.

There are clearly options available, but the decision will be dependent not only on the availability and cost of suitable body panels, but on the intended use of the finished product.

Budget Digital Subscription

Get access to over 7 years of Land Rover Monthly – that’s almost 100 issues plus the latest digital issue. The issues are fully searchable so you can easily find what you are looking for and what’s more it’s less than 10p a day to subscribe. Click here and start enjoying all the benefits now