15 December 2023

|

In the final part of our Projects series, Alisdair Cusick meets Twenty-Ten Engineering, the specialist that has made restoring classic Range Rovers its livelihood

Conceiving a project and executing it is one thing, but so far we’ve only looked at working on our own vehicle. Take the idea to its limit, and you get people for whom projects are bread and butter; the professionals. The pros take it a stage further: they’re not executing their own ideas, on their own cars. Instead, they earn their living by completing other people’s projects.

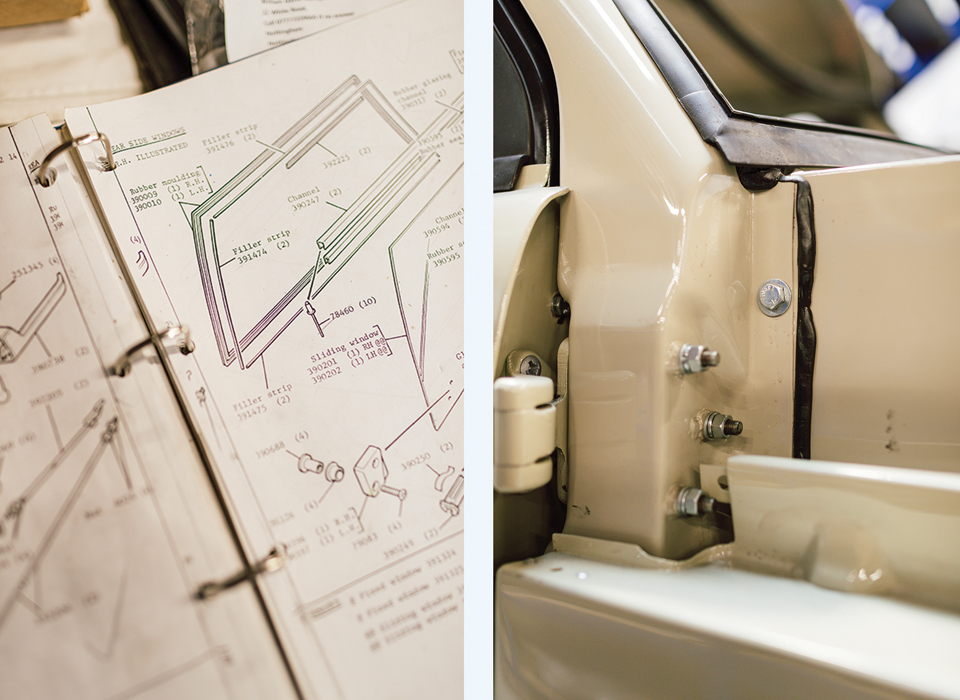

An eye for detail is essential at this level of restoration

As far as Range Rover restorers go, one name will repeatedly crop up before too long. Phil Holland is the Midlands-based expert behind Range Rover specialist, Twenty-Ten Engineering, in Redditch. His reputation is well known, principally for his level of attention to detail and finish. One of the first companies to specialise solely in classic Range Rovers, Twenty-Ten’s in-depth subject knowledge and stunning level of finish made it one of the pioneers of ultra-high-end restoration of the model. Today, the team at Twenty-Ten are respected experts at the very top of their game.

Spotless Velar engine bay mid-restoration

Those skills originate from a background immersed in the brand. Phil grew up with a modified Range Rover as a family car – the Masai Red 1973 Suffix B wore Wolfrace alloys, Rolls-Royce tyres, a Webasto sunroof and interior retrim. “Even back then, it stood out as an enthusiast’s car, and that’s what got me into Range Rovers,” recalls Phil. Incredibly, his father still has that car today.

In-house paint shop ensures the company’s high standards are met

With his father also owning Foden trucks and a Mk3 E-type as well as the Range Rover, Phil grew up helping dad fix cars – British cars at that – and Phil was smitten. Aged 15, he did his work experience at Land Rover, which convinced him he wanted an apprenticeship there. A four-year Motor Vehicle Engineering apprenticeship at Lode Lane saw Phil commuting in a rather unique way. “Aged 16, I’d bought a Suffix A Range Rover that had been bobtailed, with an SD1 engine and bucket seats,” recounts Phil. “As soon as I passed my test, that was my first car.

Period literature vital for historic accuracy, peerless build quality and attention to detail

“Joining Land Rover in 1995, for me, was a great time.” recalls Phil. “They’d got Disco, Defender; Range Rover had turned into soft dash, but with my apprenticeship in Prototype Development, I worked on P38A, Disco 2, Freelander – known as CB40 at the time – and any weird projects as one-offs: 2.8 BMW Defender, even an electric Defender,” enthuses Phil. All this meant young master Holland had a solid grounding in prototyping, engineering, mixing and matching. All the exact skills needed for what he’s doing today. “Whether it is a complete restoration that has to be kept to factory original standards or a restomod – where you’re mixing and matching to make a better, more modern vehicle – that background fed into me doing what I do now.”

Ex-factory classic on the ramp. Not all projects are full restorations

When Land Rover and Rover split in 2000, Phil found himself left on the wrong side of the company fence, bored at Rover. Devoid of the cars he was so passionate about, with voluntary redundancies appearing, he stepped forward. A spell driving HGVs, occasionally maintaining them, was huge fun, but Holland realised there was ultimately a limit to progress. In 2010 he opened Twenty-Ten; his own workshop business specialising in servicing and repairing Land Rovers.

By 2013, Phil was building a strong reputation for classic Range Rovers, interest in which he noted suddenly ramped up, as he added his first staff member. High-end restorations or modifications of Range Rovers flowed his way, meaning he could now market that specific service as a business. Come 2015, the company continued to grow, as a Range Rover customer, Chris Evans, became a business partner.

Working on projects at this level, a comprehensive stash of spares is vital

Endless supply of new fixings kept to hand

Trim spares are a must-have

With many suppliers in Redditch, it made sense to set up base there, which explains Twenty-Ten’s present location. Tragically, in 2019 catalytic convertor thieves caused a blaze which spread, destroying the building – and its contents. Nonetheless, it allowed Phil to build the fabulous workshop I sit with him in now. Packed with eight Range Rovers, a welding bay, paint booth, parts store and more, it’s a dream factory for project progress that allows them to do everything from welding to paintwork, in-house. All of that work wears the trademark attention to detail Twenty-Ten is famous for.

Twenty-Ten has grown to staff of eight

Undertaking projects at this level needs plenty of staff, and today there are eight employees, covering the whole spectrum of talents. “You need the skills to execute a plan,” says Phil who points out it isn’t easy to find the people with the right skills. The workshop today has a run of soft dash cars, including the NAS LSE prototype, a 300Tdi and a Japanese import (in for a colour change and big brake kit). In the corner sits one of the very first Range Rover prototypes, a YVB-reg Velar, gleaming as it undergoes a complete nut-and-bolt job. Thanks to its vast experience, Twenty-Ten is unfazed by anything.

Actual Ferrari leather sourced for this restoration

As if to highlight this, Phil shows me a customised LSE. Immaculate paintwork outside, but inside is the real story: black carpets, Recaro seats trimmed not just in Ferrari-coloured leather, but the actual leather Ferrari uses (Phil sourced the hides) covering the front and two rear seats. Yes, there are just two rear seats, and a centre cubby box, all finished to factory standards. “Genuinely, I care,” says Phil of his work. “That’s the difference.”

This is the world of projects where the collection of diverse professional skills in one place means just about anything is possible, as long as you have the money. And here at Twenty-Ten, budgets don’t seem too much of a problem – there’s a constant stream of projects on the go, from CSKs to In Vogues, from LSEs to rarities and prototypes. If you have the means, then commissioning the pros has much to recommend it.

Memorable projects

• Ex-Royal household Range Rover, from Balmoral Castle, associated with Princess Diana: “A great project to be very specific about getting it right,” says Phil.

• John Eales’ ‘Dakar’ Range Rover: “It feels a bit wrong to name drop, but that was a special one.”

Phil's tips

Every day is different – each car represents a unique set of customer requests

1. Make a proper plan before you start. Understand what you’ve got, and where you’re going to go with it. If you want original, how original do you want to go? Or if it’s some kind of custom build, which often can be harder, you don’t need to change plans in the middle of the project.

2. You have to know how you’re going to achieve it. This is where things differ so much from doing a project for yourself. You have to be aware of the overall budget and work to meet it.

3. Research is the key. Know what is original, or what it should be to be original. Have documents or information to hand, so you can use it. I may have a run of soft dash models, and forget something from an ’80s-spec car as I’ve not touched one. I lost so much stuff in the fire; brochures, literature etc, that is invaluable. That’s the difference in getting cars to be correct.

4. Have a trusted support network of external suppliers. Knowing you can call on other people – whether it’s a parts supplier or someone who can help with a query – to help you along is a massive bonus.

Contact: Twenty-Ten Engineering, tel: 07973 831878, twentytenengineering.co.uk

Catch up on the previous two projects in this series here.

Like to have your own Land Rover library?

Try our Budget Digital Subscription. You'll get access to over 7 years of Land Rover Monthly – that’s more than 100 issues plus the latest digital issue. All issues are fully searchable so you can easily find what you are looking for and what’s more it’s less than 10p a day to subscribe. Click here to find out more details and start enjoying all the benefits now.