07 May 2024

|

This Series I fire engine was based at ICI’s explosives factory in North Wales for 40 years. This is its story…

Today, it is known locally as Gwaith Powdwr, which translates as Powder Works, although for many years it was known as Cooke’s Works. It is now a nature reserve at Penrhyndeudraeth near Porthmadog in North Wales, but given what used to be made here, having its own fire brigade was probably very sensible.

In 1865 a factory opened on the site that manufactured explosive charges for use in the local slate quarries. In 1922 it was acquired by one Ralph Cooke, a coal mining magnate who owned another explosives factory in Essex, and he combined the two operations at the Penrhyndeudraeth site.

Following an explosion at the factory in 1928, Cooke sold part of his company to one of his rivals, Imperial Chemical Industries (ICI), ostensibly to gain access to its expertise (he probably reckoned ICI had a better approach to health and safety) and during the Second World War the factory produced over 17million hand grenades. Almost all of them were assembled by the six or seven hundred women who worked there. Apparently, their hands turned yellow as a result of the substances they were handling. ICI acquired the remaining shares in the company following Cooke’s death in 1955.

Ex-army Jeep used for fire fighting until the Series I arrived

Quite what the arrangements were for firefighting in the factory’s early days are unclear, but they presumably involved lots of horses and hand pumps. A surviving photograph shows that in the years immediately after the Second World War a military surplus Jeep with a trailer was used. This was replaced in 1955 by the 86in Series I you see here, which is now in the care of the Dunsfold Collection.

The crew with their trusty new Fire Tender

Chassis number 170600358 is a Home Market, Basic, 86in model, built to 1956 Model Year specification on 29 September 1955, and transferred to Rover’s Technical Sales Department for installation of the fire appliance equipment. The completed vehicle was despatched-out on 4 October and delivered to Rover dealer Davies of Barmouth. It was registered with the Merionethshire number AFF 218 on 17 October 1955 and the original buff logbook shows that its first owner was Cooke’s Explosives Ltd. It was taxed every year until December 1965, which was probably when its Series II successor appeared at the factory.

Hose and pump gear at the ready

The Series I must have been put to good use not long after it was delivered to ICI, because in 1957 there was an explosion at the Cooke’s factory site which killed four workers – three women and one man. The inquest found no negligence on the part of the company, and the official line was that mice had chewed through electrical cables causing a flashover.

Bonnet hose support attachs to front bumper

There was another explosion on 14 June 1988 which killed two men and injured eight more. The subsequent investigation revealed that the men were not inside the reinforced control bunker, which is where they were supposed to be when the mixing of nitroglycerine with kieselguhr, nitrocellulose, aluminium powder and salt was taking place, to produce gelignite.

Water pump control panel hangs off the rear crossmember

In a paper to the Institution of Chemical Engineers in 2003 Brian Harris, who at the time of the 1988 accident was joint managing director of Nobels Explosives Company Limited, the ICI subsidiary that managed the factory, outlined the events of the day. He was at work at the company’s plant at Ardeer, on the North Ayrshire coast.

“I received an emotional call from the Cooke’s Works manager,” he wrote. “There had been an explosion in one of the two mix houses. Two men were missing. There were fires and there had been secondary explosions. I immediately put our major emergency plan into operation. An aircraft was arranged to fly us from Prestwick to a small airfield near to the factory.

Two-piece doors have taken a battering from hitting the hose couplings

“We flew over the factory and saw the devastation on the hillside and the crowds standing around the factory gate together with fire engines, ambulances and the police. We landed and were driven through the crowds and emergency services. I had a short period of reflection with the works manager and discussed the way forward. The factory was in a safe condition. The fires were out. The second mix house had withstood the explosion of its neighbour. Two men were missing without trace. The next few days were concerned with the bereaved families and preparing a recovery plan for the factory and assisting the police and the Health and Safety Executive in their investigations.

The investigation was based on DNA analysis and confirmed that the two men who had died were in the wrong place at the time of the explosion. “During the mixing operation they should have been inside the reinforced control room bunker. Although shaken, this building was largely intact, and the men would have escaped with only minor cuts and bruises had they been inside.” But they weren’t, contrary to the company’s clearly defined procedures.

Fire hoses store alongside the truck’s water tank

German-made pump capable of shooting out 120 gallons of water a minute

Different sized nozzle ends gave a variety of water spray patterns

By the time of the 1988 accident, the Series I was apparently held in reserve, because it had been replaced by a Series II 109in fire engine, and we can only speculate what role these vehicles played as first responders when the mix house was destroyed.

The factory closed in 1995, because of a decline in the demand for explosives by the coal mining industry. The land was donated to the North Wales Wildlife Trust in 1998 and is now managed as a nature reserve, although the remains of some of the old factory buildings can still be seen around the site.

Around the time of the plant’s closure the fire engine appeared in Land Rover World magazine, and the article claims that an anonymous reader had called the publication to say that the Land Rover ‘was about to be blown-up during the decommissioning of the ICI factory’. That sounds like a bit of a tall story, so it’s time to ask those who were around at the time if they can offer any insights.

Seats replaced after the originals were wrecked by gnawing rodents

Dunsfold’s Philip Bashall remembers that his father, Brian, drove his Velar (YVB 172H) to North Wales with a trailer to collect the Series I, but only because he recalled him saying that it had been a nightmare towing it back, and that Brian had only worked out why when he was unloading it. The fire engine’s water tank was almost full and the weight of nearly 40 gallons of water splashing and surging around at the rear of the trailer was the cause of all the havoc.

Philip approached John Carroll, lately editor of Classic Land Rover magazine, who was the editor of LRW at the time the Series I was saved from an apparently explosive end, but John didn’t offer any new information.

Low mileage is evidence that the fire engine didn’t get much use

Philip had a vague memory of a letter from ICI, but this was not to be found in the vehicle’s history file, and we began to think he might have been imagining it. But after a lot of digging in the many boxes containing paperwork relating to the Bashall family’s DLR parts and servicing business, there it was – a letter on ICI-headed paper dated 23 November 1995 from Mr A D Profit, the Works Manager at the Penrhyndeudraeth factory, addressed to Brian. In the letter, Mr Profit refers to ICI director Alan Spall’s decision that the fire engine would be offered to what in those days was known as the Dunsfold Land Rover Trust. No mention of it being blown up if Dunsfold didn’t want it.

“Since we acquired it, the fire engine has spent almost the entire time in store,” says Philip. “It used to come out for our old biennial Open Weekends at the Springbok Estate, the last of which was in 2017, and there are also photos of it with some of the Collection’s other Series Is at a First Overland team reunion in late 1997, but other than that it’s been largely unseen until now.

Plenty of patina on display here

“It is in very good condition overall. Chassis and bulkhead are excellent, which is hardly surprising given that the odometer shows that it has only driven 7419 miles and spent most of its life under cover. The engine is sweet and runs well. There is a broken front halfshaft to do and a swivel and hub bearing to adjust on the right-hand front. The brakes are partially seized but will free off, and we think the linings are the ones it left the factory with. The front prop shaft is shot, possibly due to the vehicle being driven around the factory site in low-ratio all the time.

Numerals scratched into the paint. Sticker offers sensible advice

“It had a repaint at some point in its life prior to coming to us, as well as silver paint on the galvanising and on the pump, presumably because someone was trying to smarten it up. The ICI logo on the doors is hand painted but it certainly wasn’t done by a professional signwriter, or if it was it must have been after a long liquid lunch in the pub!

“Both rear corners of the tub are creased, and I think this was probably caused by a trailer jack-knifing. The rear lights have been replaced, and both doors are damaged as a result of swinging open and hitting the hoses on the front wings. The seat bases had been destroyed by mice infestation before the vehicle came to us, but the original backs are still in place. The pump runs but all the gauges were smashed before we got it.”

Land Rover offered the fire engine as a factory model

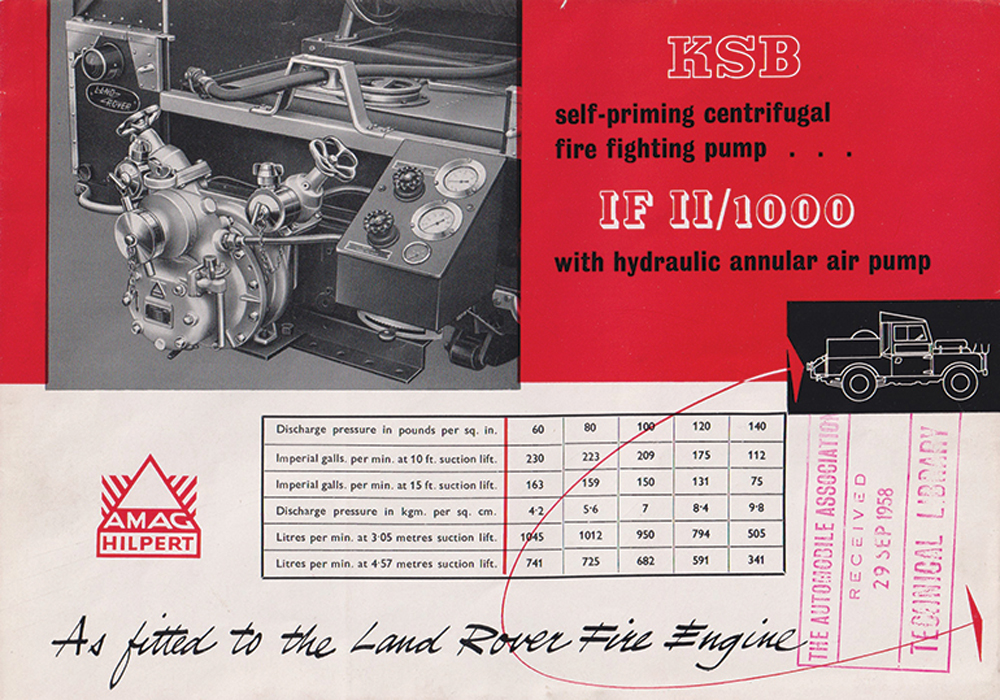

Original Pump brochure

The ICI vehicle is identical to the example depicted in Rover’s brochure dated March 1957 for their standard Fire Engine. Factory specification included the German-made KSB self-priming two-stage centrifugal pump mounted on the rear crossmember with a hydraulic annular air pump to take care of the priming, with drive coming from the centre PTO via a propshaft direct to the pump. The pump is controlled by an engine governor mounted on the pump control panel, limited to a maximum of 2850rpm.

The control panel also has a compound pressure/vacuum gauge, a second pressure gauge, oil temperature gauge, and two parallel slide-type selector valves, with the hose connections illuminated by light deflected through modified rear light casings. The pump has a capacity of 210 gallons per minute at 100psi for a 10-feet lift, and as well as feeding the 120 feet long first-aid reel mounted on a drum behind the cab, the pump can feed two full-sized 2½-inch delivery hoses.

With 40 gallons of water aboard you wouldn’t be ‘rushing’ to the fire

The first-aid reel is fed by the 40-gallon galvanised steel water tank carried between the rear wheelarches. On top of the arches are two steel stowage lockers for delivery hose lengths and other items, with canvas covers secured by spring-loaded fasteners to the sides of the vehicle.

It’s interesting that some pretty important items were listed in the brochure as optional extras including 2½-inch standard delivery hose couplings, which were carried on the bonnet, as well as things like hose blanking caps and suction hose couplings. Amazingly, the metal truck cab was not fitted as standard and was available at extra cost. The ICI example could therefore be described as ‘full-spec with all the extras’.

Even the badge got the fire engine red paint treatment

As Philip says: “It’s a genuine, unrestored and very low mileage Series I with a wonderful history, and it’s a bit of a mystery as to why it’s never really attracted much of a following. Maybe that will change and more people will take an interest in it, now that it will be spending some time this year on display in the museum.”

Like to have your own Land Rover library?

Try our All-Access Digital Subscription. You'll get access to over 7 years of Land Rover Monthly – that’s more than 100 issues plus the latest digital issue. All issues are fully searchable so you can easily find what you are looking for and what’s more it’s less than 10p a day to subscribe. Click the link above to find out more details and start enjoying all the benefits now.